"Forging the Backbone of Tomorrow’s Infrastructure”

Synergizing ore Into Refined Steel

Unveiling Precision

Ore to Reinforcement Excellence

Believing in Steel, Building with Trust

We believe in steel, not just as material, but as a symbol of unwavering commitment. Just like India's relentless infrastructure push, Gallantt Advance Fe550D TMT Rebars embody endurance, precision, and reliability. They rise to the challenge, withstand the test of time, and carry the weight of ambition. Every kilometer paved, every station built, every dream realized reflects not just the visionaries, but the silent heroes – the steel that binds, the trust that fuels. We are proud to be part of this saga, contributing to a stronger, more connected India, building the India of tomorrow, one unwavering structure at a time.

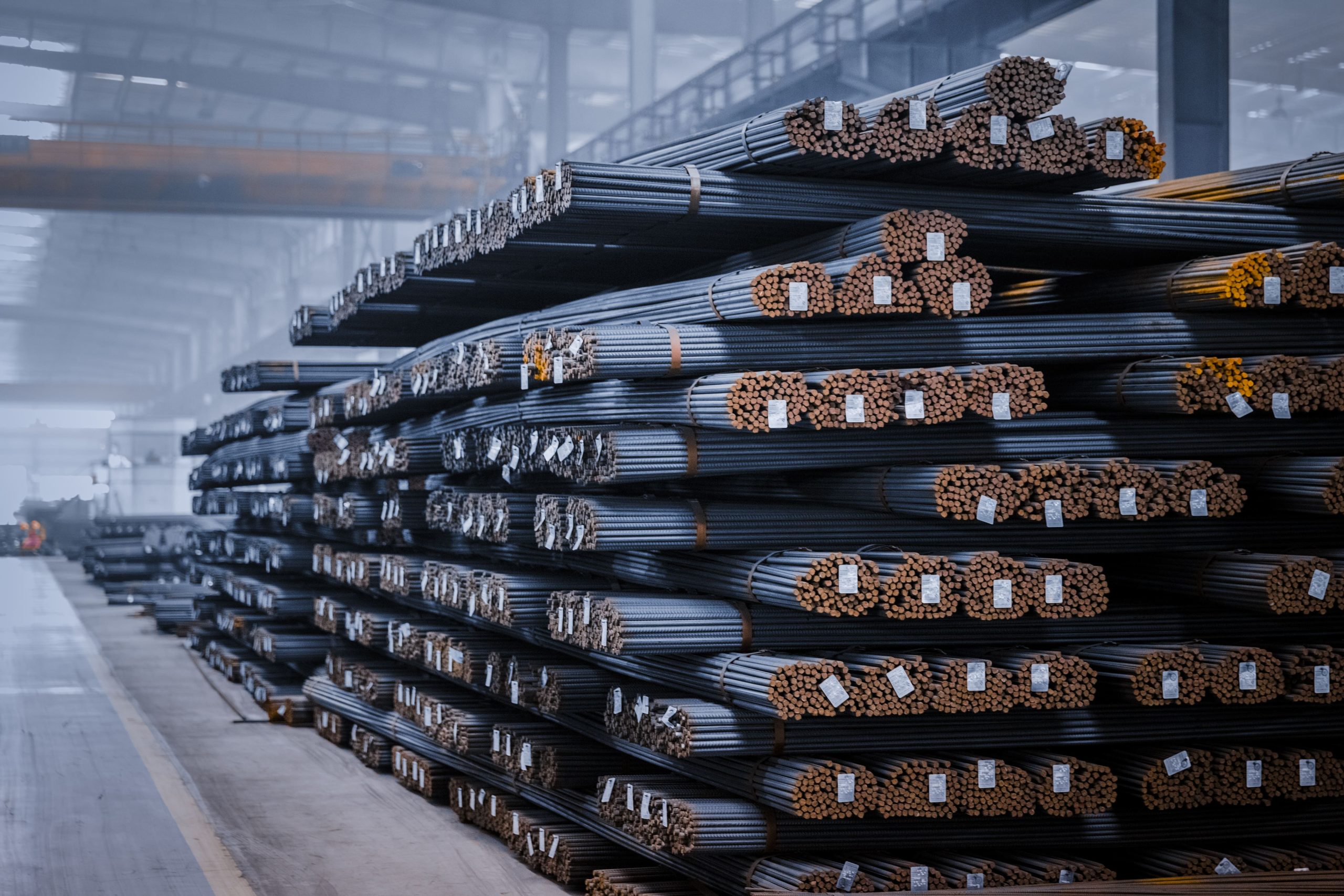

Our Product

Range

Fe550D TMT Rebars

Fe550, Fe500 , Fe500D, Fe 500CRS, Fe 500DCRS

Manufacturing Prowess

Crafting Steel Excellence

Manufacturing Prowess

Our state-of-the-art manufacturing facility embodies unparalleled prowess, integrating a sponge iron unit, steel melt shop, rolling mill, pellet plant. With precision engineering and cutting-edge technology, we ensure seamless production. deliver-ing high-quality steel products while optimizing efficiency and maintaining envision0-metal sustainability.

| Units | Total Group Capacity (TPA) |

|---|---|

| Sponge Iron | 1035000 |

| Pellet Plant | 792000 |

| Steel Melt Shop | 957000 |

| Rolling Mil | 950900 |

| Captive Power Plant | 129 MW |

Employees

0

+

Assets

0

Billion INR

Annual Sales

0

Billion INR

Steel Making

10 LAC TONS FOR ANNUM

TMT Bars

Captive Power

Cement

Manufacturing Prowess

Fully Automated At a Making

- Ladle Refining Furnace

- Rolling Mill

- Quenched Tempered In Line Steel Making

- Online Real Time Quality Monitoring

- Automatic Bar Bending, bundling & Loading

- Internationally Acclaimed Labs

- Cement Plant

- Captive power plant

- Company owned railway racks

- Railway Siding

- Wagon tippler

- Sponge iron kilns

- Pellet paint

- Steel melt shop

Manufacturing Prowess

Crafting Steel Excellence

Higher yield strength

Higher yield strength and load-bearing capacity, require less steel for the same structural integrity, contributing to overall project costsavings

Better Bonding

The double M Rib design with 360 Riblack Technology creates a robust bandbetween stool and concrete resulting in much superior bond strength

Excellent Ductility & Elongation

Excellent flexibility & uniform elongation induces superior seismic resistance propertries which minimizes the risk of demage during earthquakes safeguarding your structures & Ives

Unlocked Savings

Upto y% of direct saving on overall steal consumption due to less number of rebars required and reduced maintenance costs as corrosion-resistant properties extend the life of structures.

Strong Bonds, Solid Structures

Forging an Unbreakable Bond

What makes a strong bond?

A strong bond between TMT rebar and concrete results from a combination of factors:

- Ribbed Design : Unlike smooth bars, TMT rebar features strategic ribs that interlock with the concrete, creating a powerful mechanical grip. This prevents slippage and ensures effective stress transfer.

- Chemical Adhesion : The alkaline nature of concrete triggers a chemical reaction with the steel in the TMT rebar, forming a microscopic bond that further strengthens the connection.

- Meticulous Placement and Coverage : Precise positioning and adequate concrete cover ensure the rebar is fully encased, protecting it from corrosion and maximizing its load-bearing capacity.

M-Grip: Redefining Structural Strength

The Power of Precision: Amplifying Bond Strength with double M Ribs

TMT Bars form the backbone of every construction, be it foundation, column, beam or

the slab in any RCC structure across both in commercial and resedential projects. TMT

bars are used all projects as a prime element providing the required shape, strength,

ductility and durability to every civil structure. Our unwavering commitment to crafting

the cleanest, purest steel possible is why we've invested in cutting-edge ladle refining

furnace technology. This innovative process meticulously removes impurities by de-

sulphurisation and de- phosphorisation, lowering of gas contents, and adjusting

temperature for tapping and alloying, resulting in rebar with 20% higher tensile strength

and excellent ductility.

| Chemical Properties Constituent (Max) |

BIS Fe 550 |

BIS Fe 550 D |

Gallantt Advance Fe 550 D |

|---|---|---|---|

| Carbon | 030 | 0.25 | 023 |

| Sulphur | 0.055 | 0.04 | 0035 |

| Phosphorus | 0.055 | 0.04 | 0.035 |

| Manganese | - | - | >= 0.60 |

| Sulphur Phosphors | 01 | 0.075 | 0.07 |

| Mechanical Properties Parameter (MIN) |

BIS Fe 550 |

BIS Fe 550 D |

Gallantt Advance Fe 550 D |

|---|---|---|---|

| Yield Strength (N/mm²) | 550 | 550 | 575 |

| Ultimate Tensile Strength (N/mm²) | 585 | 600 | 650 |

| Elongation (%) | 10 | 14.5 | 18 |

| UT/YS Ratio | 1.06 | 1.08 | 1.15 |

| Size (MM) |

BIS Standard Kg/Mtr (Tolerance) |

BIS Standard Kg/Mtr. (AVG) |

Gallantt Kg/Mtr. (Tolerance) |

Gallantt Kg/Mtr. (AVG) |

|---|---|---|---|---|

| 8 | +7 | 0.395 | +3 | 0.382 |

| 10 | +7 | 0.617 | +3 | 0.587 |

| 12 | +5 | 0.888 | +2 | 0.864 |

| 16 | +5 | 1.580 | +2 | 1.541 |

| 20 | +3 | 2.470 | +1 | 2.433 |

| 25 | +3 | 3.856 | +1 | 3.810 |

| 32 | +3 | 6.310 | +1 | 6.212 |

LRF Refining Excellence

TMT Bars form the backbone of every construction, be it foundation, column, beam or

the slab in any RCC structure across both in commercial and resedential projects. TMT

bars are used all projects as a prime element providing the required shape, strength,

ductility and durability to every civil structure. Our unwavering commitment to crafting

the cleanest, purest steel possible is why we've invested in cutting-edge ladle refining

furnace technology. This innovative process meticulously removes impurities by de-

sulphurisation and de- phosphorisation, lowering of gas contents, and adjusting

temperature for tapping and alloying, resulting in rebar with 20% higher tensile strength

and excellent ductility.

Contact Details

Contact Us

Get in Touch

For inquiries and feedback, please fill out the form below.

OUR BUSINESSES

Other

Products